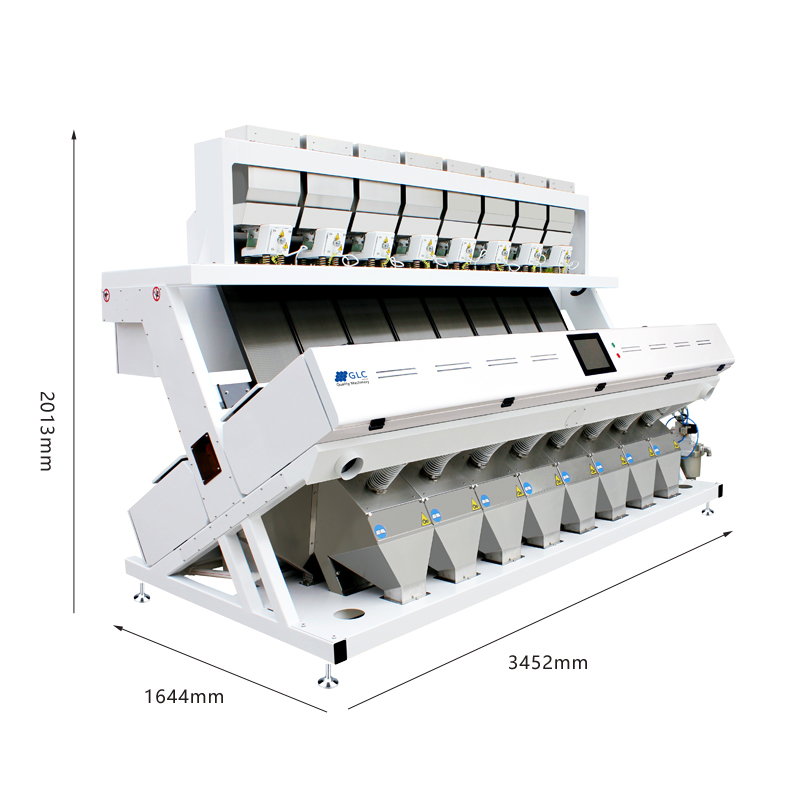

Flaxseed Colour Sorter With High Freqency Ejectors

The granular material enters the material hoppers through the lifting equipment, and the bottom of the material hoppers are connected with the vibratory feeders. Affected by gravity, the material falls into the vibratory feeders. The vibratory feeders vibrates material onto the chute ,where it spreads evenly along the chute into a single-layered stream of material (ideally) . After a period of time, the material slides out of the chute and enters the detection area (sorting area). There are one (or more) sets of industrial linear sensors (cameras) (CCD or CMOS) at front and rear direction of the sorting area. The sensor scans the optical information of the material and transfer it to the signal processor (FPGA) for processing. With the certain algorithm processing, after a certain of period(delay time) ,the electromagnetic valves (Ejectors) are controlled to release the high-pressure air pulse to the nozzle, and the bad material (set by algorithm) passing through the nozzle is blown into the rejects outlet hopper. Meanwhile, the good material slides directly into the accepts outlet hopper, due to no operation of the ejectors when the material passes through the nozzle. This completes one sorting process by the sorter.

1.Industrial Linear Sensors (Cameras)

RGB full color tri-chromatic CCD image sensors (infrared sensors optional) with

high image resolution 5400*3 pixel can identify tiny defects up to 0.003 mm2

2.LED Lamp

Imported LED and unique light design ensures high efficient uniform illumination and super long life span.

3.High Frequency Ejector

High temperature high frequency electromagnetic coupling ejector with 5-10 billion ejections life and with low air consumption

4.Heavy Flow Chute

Wide chute design with special anodizing treatment process secures high flow capacity and stability of material flow. primary, secondary, tertiary, quadruple sorting process mode design available

5.Professional hardware design

Decades of sorting machine design experience ensures that the hardware design of the machine conforms to the principles of fluid mechanics, to avoid material jumping or blocking

6.Simplified GUI

Simplified customer-friendly GUI design greatly enhances ease of operation.

7.Customized algorithm

Special algorithm is customized to improve the sorting accuracy and carry-over ratio,according to the different optical and physical properties of the each materials.

8.Remote &mobile phone control

Engineer can help end users to modify the machine online and end users can easy control and check of machine status.

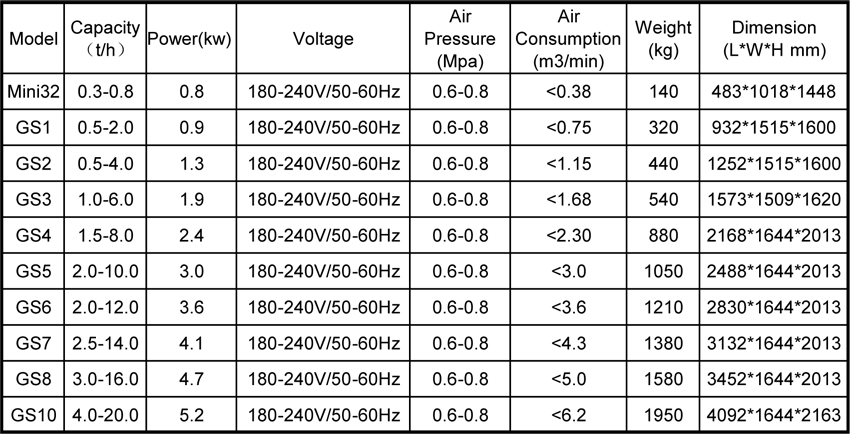

PARAMETERS OF Flaxseed Colour Sorter

APPLICATIONS:

Rice,Beans,Seeds,Nuts,Dryed Fruit And Vegetables,Plastic,etc

1.How to get the right type colour sorters for me?

To get the fast and best answer,we need to confirm:

A.what kind material you want to separate by our sorter?

B.What is impurity inside your raw material(unsorted) and each percentage rate %(estimated)?

C.How many tons per hour of the capacity you need?

D.Show us the raw material photos(high definition). point out which is good and which is bad.

E.Do you have the budget to purchase of our sorting machine?

2.How long it will be to get the sorter after paid?

It is 10-30 working days depends on situation. Holidays or peak sales season may be slow.

3.Do you have the warranty for your machine?

Yes,we have warranty for our machine for 1 year. You can also buy an additional warranty period.

During the warranty period of our color sorter machine,we will send the parts to our user for total free.If out of warranty,we will charge a reasonable fee for the parts.

4.Do I need to buy spare parts?

It depends.usually,our sorting machine will not broken in short time. If you really need some,we can sell you some and send together with the machine.

5.Do you supply air compressor,elevators,etc equipment?

Yes,we can offer you air compressor(air tank,air dryer,air filters) and elevators with compatible model for our color sorter machine.

6.It is easy to use your machine?

Yes. Usually,you can just start our sorters after installation,because we already finished the modification in our factory with the specified material. We will also offer you installation drawing as well online guidance.We had helped hundreds of customers to install and start machine online during covid-19.

7.It is necessary to send an engineer to help us for guidance of installation and modify the machine?

Usually no need. If you are end user and have many materials to separate by one of our machine,we suggest to send an engineer to help you and teach you to operate of our sorter.

You need to pay visa,round trip airplane tickets,accommodation,food,and extra salary of our engineer,etc.

8.Does your machine have our language except English?

We have language like Russian and Spanish. If you want to put other language into our sorting machine. We will insert the document into our sorter after translation from English with the help from your side.